During warm spring days and mild summer nights, people think more about cooling their homes than heating them. But when fall weather turns cold and days pass toward winter, thoughts change to throwing on an extra clothing layer, turning up the thermostat and letting the furnace take over.

Most people probably take their home’s furnace for granted, except when it’s scheduled for seasonal servicing or bill-paying time. How often they service their furnace or how high the bill runs depend mainly on their type of furnace and what fuel source it consumes.

Not every American home depends on a forced-air, combustible fuel furnace for a central heating system. Different forms of heating include passive sources that radiate heat, convection sources that transfer energy from hot to cold and conduction sources where objects are heated by direct contact with a burner. Radiators, fireplaces and in-floor heat are prime examples used in place of forced air or sometimes as auxiliary complements.

Forced Air Furnace Fuels

Today, coal and wood-fired furnaces are mostly relegated to museums. Oil is common, but it’s fading as cheaper, cleaner and more efficient fuels replace this carbon-emitting substance. Electric forced air furnaces have their place, but they are expensive to operate and can go dead-in-the-water when the power fails in harsh winter storms. Natural gas furnaces are highly popular in urban and suburban areas that have access to the supply grid. And last, but far from least, are furnaces powered by propane.

Most people think of propane as that gas in the white bottle attached to their barbecue that inconveniently runs dry when their steak just went on the grill. They don’t consider that in many homes across the nation, propane does far more than heat the backyard grill. Besides firing furnaces, propane powers ranges, stoves, dishwashers, dryers, hot water heaters and radiant heat boilers, space heaters, swimming pools and outdoor patio warmers.

Propane for all that? Isn’t that expensive and inefficient, never mind only found in remote places where other fuels are scarce? No, not at all. In fact, nothing could be further from the truth.

According to the United States Energy Information Administration (EIA), an independent statistical agency and part of the U.S. Department of Energy whose sole purpose is to provide unbiased and reliable information on all energy sources, propane is immensely popular in America and for exceptionally good reasons.

The EIA reports that out of 107 million households in the nation, 9.4 million depend on propane fuel for different applications. That may be from only their barbecue to their entire fossil fuel needs. Statistics show that 53 percent of propane household consumers rely on propane as their primary heating fuel. That’s just under five million homes that operate propane boilers, propane furnaces and fireplaces for heating.

Propane is so popular because it provides a clean, safe and economical heating commodity that’s totally reliable and always available — regardless of the service area and seasonal interruptions that shut down furnaces fueled by oil, gas or electricity. Propane provides instant heat with low emissions. It’s the greenest carbon fuel in waste, pollution and other impacts on the environment.

Propane furnaces are not new. Nor are they a secret held only by homeowners who’ve experienced the benefits of propane furnaces, know the costs of propane furnaces and weighed the pros and cons of using propane gas to heat their homes. But, at one time, these owners all wondered what propane is, what propane furnaces are and how propane furnaces work. They were also curious about the costs of propane.

What Is Propane?

Propane is a carbon-based fuel that’s a by-product of the crude oil and natural gas production process. Refining oil and gas involves extracting materials like butane and propane to prevent these liquids from condensing in distribution lines and causing corrosive damage. Propane is not manufactured for its own sake. Rather it’s a necessary derivative from the primary oil and gas industry that’s then packaged and sold as a value-added energy commodity.

In raw form and at normal temperature and atmospheric pressure, propane is in gas form. For practical reasons, propane is stored and shipped in pressurized containers. High pressures cause propane to liquefy and cool. It’s then labeled as liquefied propane gas (LPG) and is the reason why tanks are cold and sometimes covered in frost. Once liquefied propane is released from pressure, it returns to a gas state and is transferred from its container through a regulator that reduces pressure and sends the combustible gas through a line and to the barbecue or furnace burner.

Propane Grades

HD-5 is high-grade LPG that’s used for residential use. It’s the most common propane type available in the United Sates and is also used as engine fuel in the transportation industry. HD-10 is lower-grade fuel suited for commercial and industrial application.

Propane can’t be economically shipped by pipeline. Commercial transportation is accomplished by rail cars or large highway rigs. Local distribution is done by smaller trucks that can deliver to anywhere on the continent that has roads or by vessel to remote lake or coastal sites.

Propane is widely available across the country, even in remote areas. Propane stores well. It’s inherently stable and is safely kept in steel tanks. Storage container sizes range from two-pound camp-stove cylinders, to 20-pound barbecue tanks to 5,000-pound in-ground containers. This versatility makes propane a prime heating choice where other fuels aren’t practical or economical. It includes fueling forced air furnaces.

What Are Propane Furnaces?

Propane furnaces work on the same principle as other forced air furnaces except that propane is used in place of oil or natural gas to burn or electricity that uses resistance to produce heat. There are pros and cons to all forced air furnace fuels, and each has its particular application depending mostly on local factors.

Propane forced air furnaces are ideal where other fuels are scarce, expensive or can’t be delivered. They’re also perfect in rural areas where power interruptions occur because propane furnaces don’t depend on electricity to operate their burner. Although most forced air fans use electricity, propane burners can operate effectively and radiate heat on their own.

Size and Versatility of Propane Furnaces

Propane furnaces are compact and can be placed in tight locations like crawlspaces in homes on foundations and in mechanical closets on manufactured homes. This is ideal for smaller applications like recreational properties, mobile units and the new trend towards tiny homes where space is a premium.

Energy efficiency is a key concept in selecting a propane furnace. Efficiency is rated in a percentage called the Annual Fuel Utilization Efficiency (AFUE). This is the U.S. Department of Energy’s (DOE) standard of determining the amount of potential energy being available compared to the furnace’s actual usage or output. The minimum efficiency standard allowed by the DOE is 80 percent with many high-efficiency propane furnaces on today’s market having AFUE ratings of 90 to 98.5 percent efficiency.

That means the best performing, high-efficiency propane furnaces turn nearly all of their available fuel energy into heat. This heat energy output is measured in a uniform standard known as Thousand British Thermal Units per Hour (MBTUH). Propane furnaces are available in output sizes from 15 MBTUH to over 100 MBTUH.

While there’s a wide variety of sizes and efficiencies in propane furnaces, most work on the same principles and employ similar components.

How Do Propane Furnaces Work?

Propane furnaces work by combining three components in a system:

- The fuel supply and delivery

- The burner or the combustion heat exchanger

- Air distribution network that consists of supply and return air

Quite simply, propane fuel is delivered to the furnace and burned. Then, the heated air is blown about the home. Once the air has cooled, it’s returned to the furnace and recycled.

No matter the location or application, propane is kept in a government approved outdoor storage container. This is mandatory by regulation, and there is a maximum life limit to the storage tank. Propane tanks cannot be supplied nor filled by any person or business that is not licensed, trained and certified in propane handling safety.

Propane Installation Safety Certification

Infractions of propane safety laws are serious matters and may result in prosecution as well as voids in warranty and refusal of insurance claims when something goes wrong. A homeowner should never attempt to install, modify or do any work on a propane furnace or major components. Propane is a volatile, explosive substance if handled improperly. Work other than regular filter changing and cleaning must be left to a licensed professional service company.

Propane delivery lines run from an outdoor regulator and shut-off through a low-pressure metal piping or tubing system and supply gas to the burner or heat exchanger that sits at the core of the furnace unit. Ignition is controlled by a remote thermostat, and the burner fires for as long as an increase of heat is required by the thermostat setting.

Older, less efficient propane furnaces had standing pilot lights where a small flame continually burned and then ignited the larger heat exchanger fire upon a thermostat signal. Today, all high-efficiency furnaces have electronic ignition that directly lights the burner on demand. This alleviates the unnecessary fuel wasted by the pilot light while it burned continuously.

Low-efficiency furnaces have a single-stage burner where exhaust gasses are expelled into the chimney flue and to the outdoors. High-efficiency propane furnaces have a dual-stage system where exhaust is diverted to a secondary combustion chamber where residual fuel in the exhaust is re-consumed and burned back into more energy. These high-efficiency units are called condensing furnaces.

Condensing Furnaces

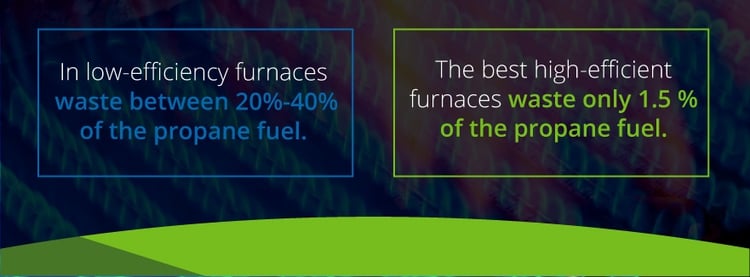

Nearly all the fuel in a high-efficiency propane furnace is used, and the chief by-product is condensed water that drains away. In low-efficiency furnaces, the combination of pilot light and exhaust contents waste between 20 and 40 percent of the propane fuel. The best high-efficient furnaces waste only 1.5 percent.

Combustion requires three ingredients — air, fuel and ignition. Without any of these, combustion cannot take place. Combustion in propane furnaces also needs the right combination of fuel and air mixture and the ratio needs to be appropriate. This ratio is called the “limit of flammability” and needs to be between 2.2 and 9.6 parts of propane per 100 parts of air. While “rich” combustion can occur at the higher mixture range and “lean” combustion at the lower, the ideal range is four parts propane and 96 parts air.

Once the burning heat exchanger has reached operating temperature, the furnace fan is activated and blows air across the face of the burner and out into the supply side of the forced air ducting system. This delivers air heated to approximately 120 degrees Fahrenheit to each room that has an outlet register.

The rolling air in each room with an open register works on a convection principle. Warm air rises toward the ceiling, and cold air is forced back at the floor. Objects in the room, people included, are warmed by air movement. Cooler air is then returned to the furnace by passive ducts, and this air is then reheated in a continuous cycle.

High-efficiency propane furnaces also employ other high-technology features such as programmable thermostats that can be pre-set for peak times as well as ultra-quiet multi-stage blowers. Furnaces come in a variety of configurations from horizontal cross-flow to upright, and they work with passive or power vented exhausts.

The same heat exchange principle used in propane forced air furnaces also applies to propane boilers for hot water that heat homes utilizing hydronic, in-floor radiant systems. Radiant heat systems are more expensive than forced air furnaces in their installation costs. The fuel costs of propane boilers are similar to consumption costs in furnaces.

Costs of Propane Furnaces

Propane furnaces are similar to gas and oil fueled units in their cost to purchase materials and in their labor to install. High-efficiency furnaces are more expensive than low-efficiency models, but they will pay back in the long run due to the savings in propane.

As an overall annual heating fuel cost, propane is similar to oil — less expensive than electricity but more than natural gas. The cost of propane as fuel varies with final delivery location and a number of market factors. Some price influences are common to all petroleum products. Some are unique to propane as a consumable commodity.

Factors that affect propane prices include:

- Crude oil and natural gas prices. Although propane is a by-product of both oil and natural gas, the current market prices of each parent commodity trickles down to propane.

- Supply and demand balance. Propane supply is subject to changes in national and international demand as well as production challenges like weather, changes in regulation and inventory levels.

- Seasonal demand. Residential propane demand is much higher in the winter, especially in cold climates. This creates peak demand periods where prices can spike unless a cap agreement is in place with the supplier.

- Proximity of supply. Propane can only be delivered by container. Logistics from travel costs increase propane unit costs.

- Markets served. Residential propane consumption is small compared to the overall propane market. Certain areas may have more commercial, industrial and transportation demand than housing. Certain increases and decreases in these markets can have a sudden and dramatic impact on home propane prices.

Overall, the benefits of propane furnaces are significant. Propane is a clean, safe and affordable home heating fuel. Propane is a truly green fossil fuel that leaves a minimum environmental footprint. It has minimal carbon dioxide discharge and is not polluting if a leak happens and propane escapes. Propane won’t soak into the ground like oil. It’s also non-toxic and merely dissipates into the atmosphere.

Propane furnaces warm countless people across America and will continue to do so for years to come. At Smart Touch Energy, we provide warmth to homes across northeastern America. We’re heating experts with eight decades of supplying fuel and furnace service to homeowners, ensuring they stay warm in the coldest months and have a plentiful supply year round.

Use propane as a major fuel source? Enter your ZIP code to see if we deliver propane in your area!